Reclaim. Reuse. Reimagine – Textile’s Water Future with SEDL

Vimarsh Verma – Director Operation, SEDL, Mohali, Punjab, India

Haresh Shandilya – Research and Process Engineer, SEDL, Mohali, Punjab

How do we continue to innovate and grow without exhausting our water resources?

The answer lies in circular water recovery. What if textile manufacturers could eliminate dependence on external water intake and operate in a closed-loop, sustainable system? With SEDL’s Smart Energy Driven Solutions for Textile Effluent, that future is not only possible – it is already here.

Every textile unit generates large volumes of effluent, rich in dyes, salts, and chemicals. Traditionally, this is considered waste, requiring costly treatment before disposal.

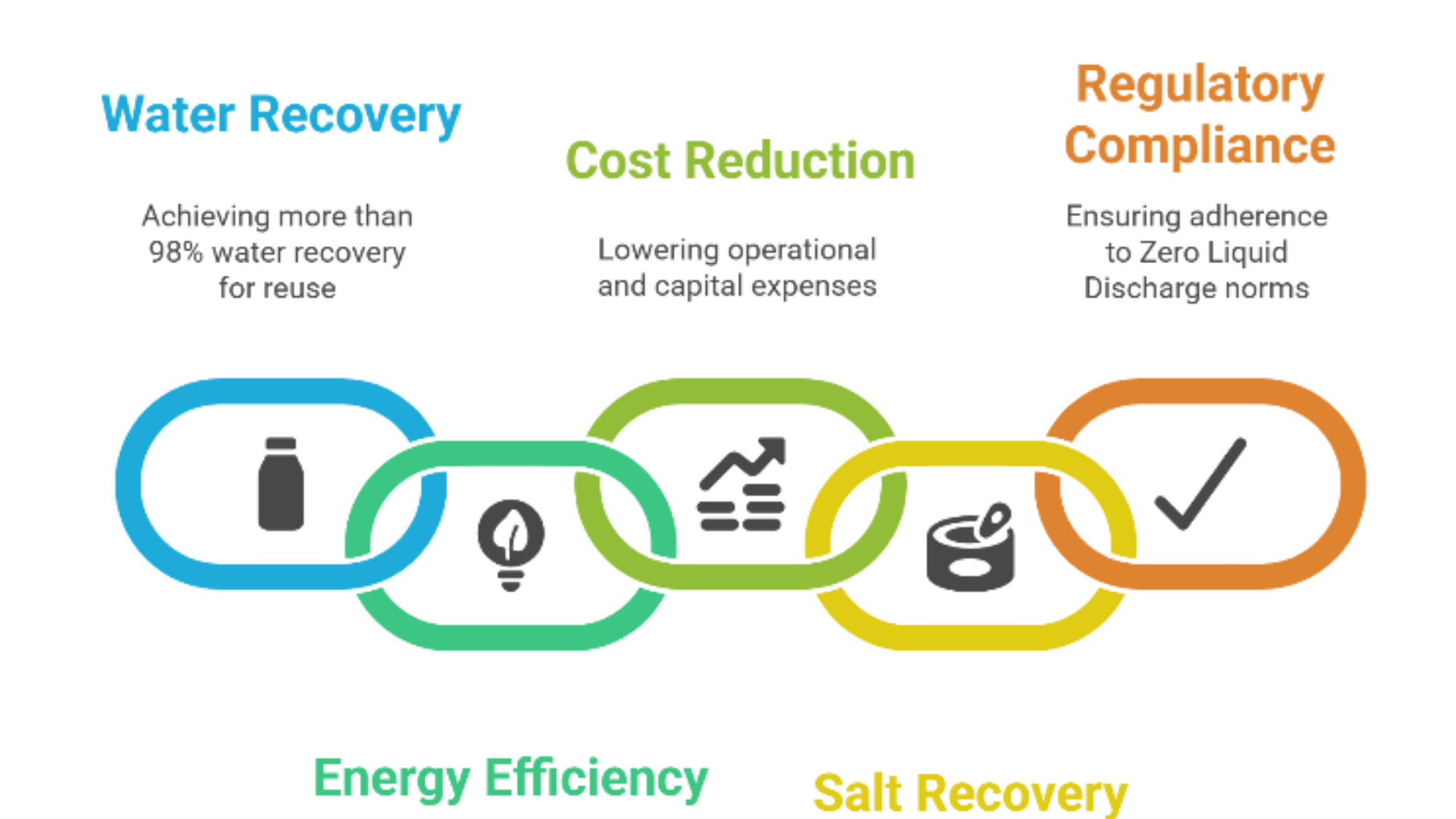

SEDL changes this perspective. With their effluent recovery system, more than 98% of pure water can be recovered directly from textile wastewater. The recovered water is distilled-equivalent quality, making it perfectly suitable for reuse in even the most sensitive textile processes.

What was once a major challenge – wastewater – is now the key to building a sustainable, resilient textile industry. By adopting SEDL’s solution, textile manufacturers don’t just solve their wastewater issue; they unlock new efficiencies and long-term benefits.

The message is clear: the textile industry of tomorrow will no longer depend on freshwater intake it will thrive on smart recovery and reuse.

With SEDL’s advanced solutions, the textile industry is entering a new era where water challenges are transformed into opportunities. A self-sufficient, circular water model ensures reduced dependency, lower costs, and enhanced sustainability. Truly, a win-win situation for business, environment, and society.

Closing the Loop: How SEDL is Enabling a Water-Independent Textile Industry

Closing the Loop: How SEDL is Enabling a Water-Independent Textile Industry A New Vision for Wastewater inthe Textile Industry

A New Vision for Wastewater inthe Textile Industry Evaporate the Waste, Elevate the Worth: A New Era in Water Recovery

Evaporate the Waste, Elevate the Worth: A New Era in Water Recovery Driving Innovation in Industrial Solutions – The SEDL Advantage

Driving Innovation in Industrial Solutions – The SEDL Advantage Automation & Efficiency: How SEDL is Transforming Industrial Operations

Automation & Efficiency: How SEDL is Transforming Industrial Operations