Efficient. Compact. Engineered for Maximum Energy Recovery.

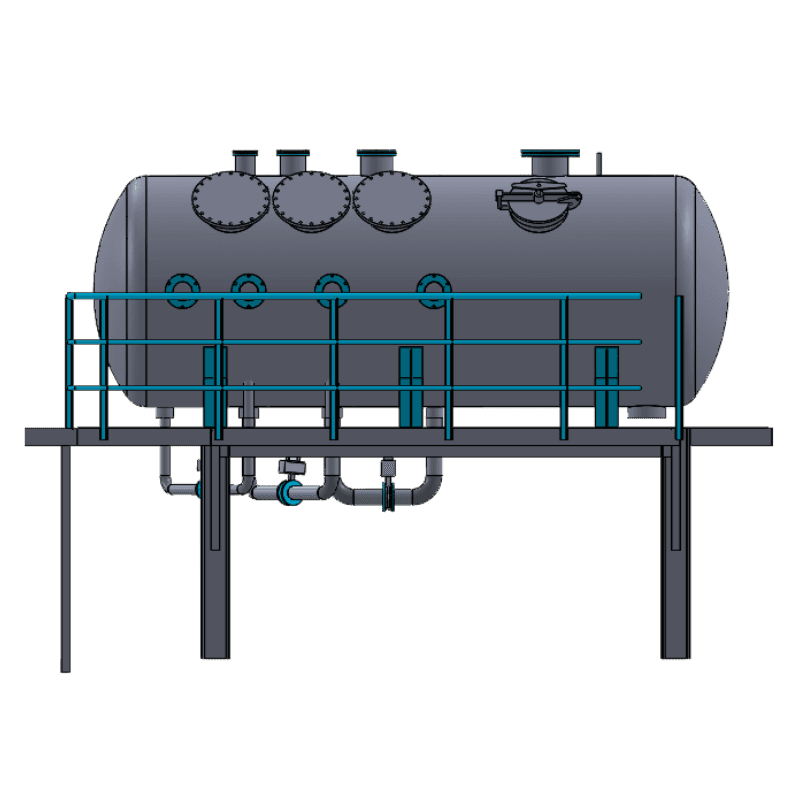

SED’s Condensate Flashing System, commonly known as FLASH CIGAR®, is a heat recovery mechanism designed to extract energy from condensate streams. Using a horizontal multi-chambered flash vessel, it recovers condensate heat as flash vapor, eliminates the need for multiple condensate pumps, and simplifies plant condensate management.

Ideal for modern sugar factories, FLASH CIGAR® enhances energy efficiency, reduces operational complexity, and ensures sustainable steam utilization.

How ItWorks?

Condensate Heat Recovery

Flash Vapor Generation

Centralized Condensate Handling

Multi-Chambered Flow

Monitoring & Maintenance

Key Advantages

Energy Efficiency

Flash vapors save the equivalent amount of exhaust steam, reducing overall energy consumption.

Streamlined Operations

Centralized condensate handling with fewer pumps simplifies plant operation.

Compact & Space-Saving

Horizontal multi-chambered design minimizes footprint while maximizing performance.

Seamless Integration

Compatible with existing or new sugar plant infrastructure for easy adoption.

Stable Operation

Eliminates hammer effects, maintains vacuum integrity, prevents back pressure buildup, and minimizes condensate losses.

Low Maintenance

Lightweight stainless-steel construction, hinge-type manholes, and sparged tube entries enable fast, simple maintenance.

Energy Efficiency

Flash vapors save the equivalent amount of exhaust steam, reducing overall energy consumption.

Seamless Integration

Compatible with existing or new sugar plant infrastructure for easy adoption.

Streamlined Operations

Centralized condensate handling with fewer pumps simplifies plant operation.

Stable Operation

Eliminates hammer effects, maintains vacuum integrity, prevents back pressure buildup, and minimizes condensate losses.

Compact & Space-Saving

Horizontal multi-chambered design minimizes footprint while maximizing performance.

Low Maintenance

Lightweight stainless-steel construction, hinge-type manholes, and sparged tube entries enable fast, simple maintenance.

Salient features

Horizontal multi-chambered flash vessel for efficient energy recovery.

Customized, lightweight stainless steel construction to match plant capacity.

Sparged tube entry for pre-flashing of condensate.

Inverted siphon control valves for chamber-to-chamber transfer.

Efficient separation of vapor and liquid condensate.

Hinge-type manholes and sight glasses for inspection and maintenance.

Pressure and temperature monitoring with recirculated condensate flow control.

Applications Across the Sugar Industry

FLASH CIGAR® is ideal for:

Raw Sugar Mills

Refineries

Multi-Effect Evaporation Systems

High-Capacity Factories

Why Partner with SED?

SED combines advanced condensate flash design, centralized handling, and process expertise to deliver measurable gains in energy efficiency, condensate recovery, and operational reliability. FLASH CIGAR® ensures sustainable steam utilization, minimal maintenance, and seamless integration with modern sugar plant operations.

Frequently Asked Questions

Revolutionizing Energy Recovery. Setting New Standards.

Maximize energy efficiency, reduce steam consumption, and simplify condensate handling with SED’s FLASH CIGAR® - engineered for compact, sustainable, and high-performance sugar plant operations.