Efficient. Compact. Engineered for Maximum Heat Recovery.

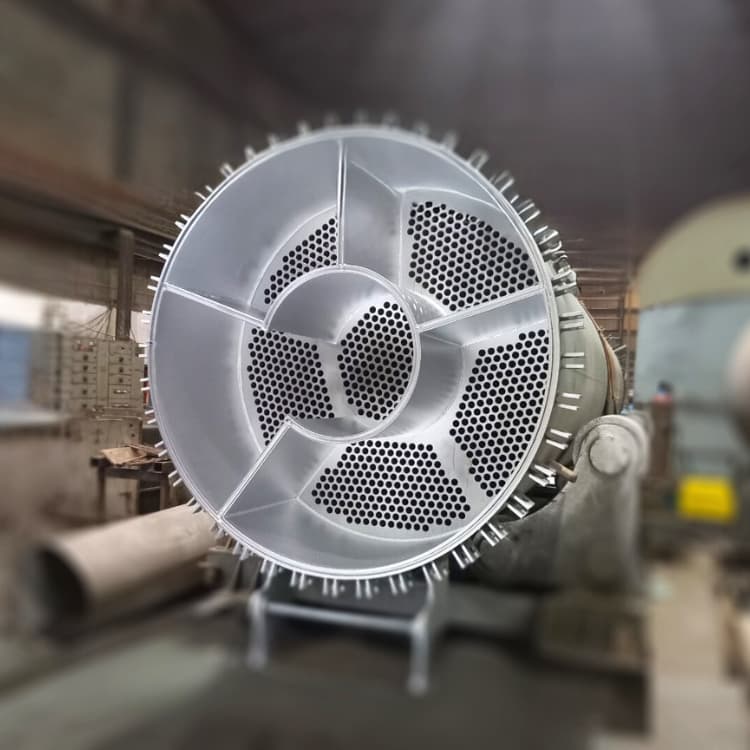

SED’s Shell & Tube Condensate Heater, also known as a Duplex Heater, is a high-efficiency liquid - liquid heat exchanger designed for juice heating prior to clarification in sugar processing plants. Its multi-pass configuration enables compact installation, maximizes heat transfer, and reduces operational heating surface requirements.

Built to handle variable flow rates and thermal loads, the heater improves thermal efficiency, reduces steam consumption, and optimizes condensate utilization - delivering a sustainable, energy-efficient solution for modern sugar mills.

How it works

Series Installation for Maximum Recovery

Countercurrent Flow

Multi-Pass Layout

Efficient Thermal Absorption

Compact Design

Key Advantages

Maximized Condensate Heat Recovery

Efficient preheating of juice reduces energy losses and improves overall thermal efficiency.

Reduced Steam Consumption

Lower approach temperatures and optimal heat transfer minimize additional steam requirements.

Compact & Space-Saving

Multi-pass design requires less footprint without compromising heating surface.

Enhanced Condensate Utilization

No heat is rejected to the cooling tower, leaving surplus cooled condensate available for make-up water.

Supports Efficient Vapor Management

Maximizes vapor availability from later effects for other consumers within the plant.

Maximized Condensate Heat Recovery

Efficient preheating of juice reduces energy losses and improves overall thermal efficiency.

Enhanced Condensate Utilization

No heat is rejected to the cooling tower, leaving surplus cooled condensate available for make-up water.

Reduced Steam Consumption

Lower approach temperatures and optimal heat transfer minimize additional steam requirements.

Supports Efficient Vapor Management

Maximizes vapor availability from later effects for other consumers within the plant.

Compact & Space-Saving

Multi-pass design requires less footprint without compromising heating surface.

Applications Across the Sugar Industry

SED’s Shell & Tube Condensate Heater is ideal for:

Raw Sugar Mills

Refineries

Multi-Effect Evaporation Systems

High Capacity Plants

Why Partner with SED?

SED combines advanced heat exchanger design, multi-pass optimization, and process expertise to deliver measurable gains in energy efficiency and condensate utilization. From concept to commissioning, our solutions enable sustainable, cost-effective operations while ensuring consistent sugar quality and plant performance.

Frequently Asked Questions

Revolutionizing Heat Recovery. Setting New Standards.

Optimize energy efficiency, condensate utilization, and sustainable operations with SED’s Shell & Tube Condensate Heater - engineered for reliable performance, compact design, and superior thermal efficiency.