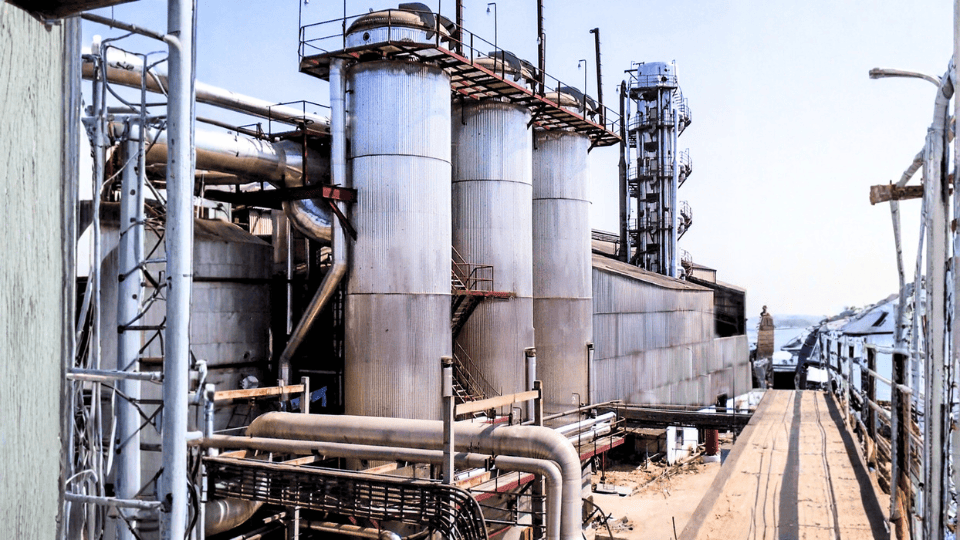

Falling Film Tubular Evaporator

A Falling Film Tubular Evaporator is a versatile and highly efficient technology for concentrating liquids, especially for heat sensitive materials due to its excellent heat transfer characteristics and short retention time. It operates on the principle of creating a thin film of liquid continuously flowing down inside the walls of vertical tubes, which are externally heated with steam. Low pressure and temperature steam can easily be used for evaporation which prevents thermal degradation or alteration of sensitive compounds, making them ideal for industries like sugar, pharmaceuticals, dairy, chemicals etc.

Operating Principle

HEAT TRANSFER

FEED DISTRIBUTION

EVAPORATION TERMINOLOGY

ENTRAINMENT SEPARATION

Why Choose MVR-based LTE®?

Enables multi-effect evaporation at low ∆T to maximize energy-efficiency.

Enables to accommodate more heating surface at low footprint area.

Designed to facilitate the lowest possible inlet exhaust steam pressure and temperature at the evaporator station for enhanced energy efficiency.

Facilitates reduced steam consumption by enabling the transfer of the major vapor consumer to later effects.

Quick-opening dish end mechanism enables the reduction of cleaning cycle time.

Enables multi-effect evaporation at low ∆T to maximize energy-efficiency.

Facilitates reduced steam consumption by enabling the transfer of the major vapor consumer to later effects.

Enables to accommodate more heating surface at low footprint area.

Quick-opening dish end mechanism enables the reduction of cleaning cycle time.

Designed to facilitate the lowest possible inlet exhaust steam pressure and temperature at the evaporator station for enhanced energy efficiency.

Salient Features

Optimized design achieving higher heat transfer rates with minimum residence time.

Ensures uniform juice distribution to prevent tube dryness with minimum recirculation and maintain consistent heat transfer.

The central juice inlet mechanism improves uniform juice distribution and minimizing external piping complexity.

Quick-opening dish end with integrated juice distributor reduces the cleaning cycle time.

Applications Across Industries

SED Jet Ejectors are widely used across industries for vacuum generation, gas evacuation, and vapor handling:

Sugar and Sweeteners

Dairy and Food Processing

Pharmaceuticals and Nutraceuticals

Specialty Chemicals

Bio-based Industries

Why Partner with SED?

At SED, innovation is more than design — it’s about partnership. We collaborate closely with clients to engineer evaporation systems that deliver measurable gains in energy performance, product quality, and sustainability.

From concept to commissioning, our solutions are backed by process expertise, manufacturing excellence, and global service support — making SED a trusted partner in your operational success.

Frequently Asked Questions

Revolutionizing Efficiency. Redefining Standards.

Experience next-generation evaporation technology with SED’s Falling Film Tubular Evaporator — engineered for high performance, reliability, and sustainability.