Precision. Performance. Engineered for Superior Juice Clarity.

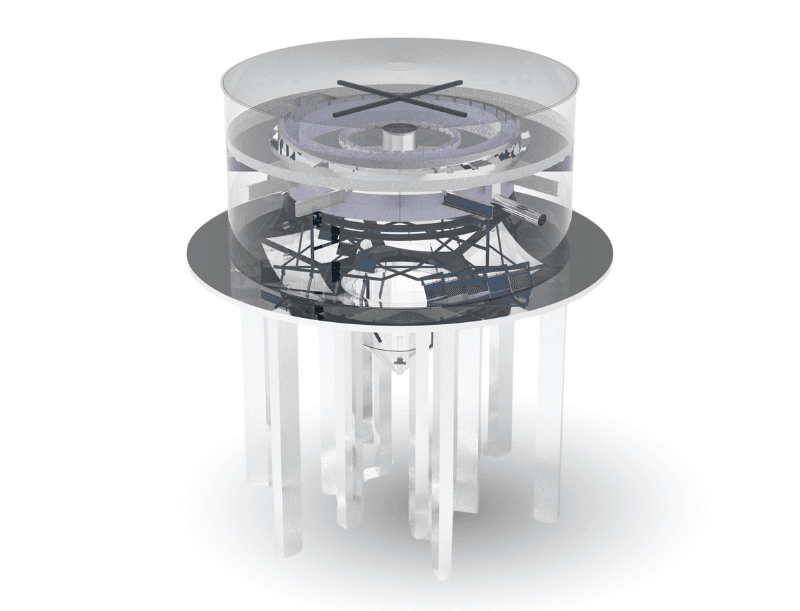

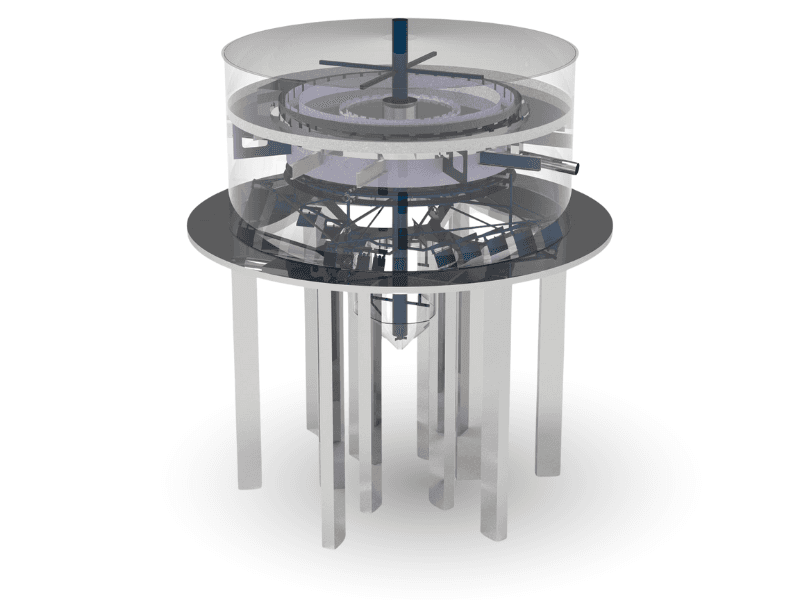

SED’s Short Retention Time (SRT) Clarifiers are high-efficiency vessels designed to separate mud from treated juice rapidly while maintaining ultra-high clarity and minimal sugar degradation. With a vertical cylindrical design, optimized juice feed, and robust mud withdrawal system, SED SRT Clarifiers deliver maximum separation efficiency in minimal footprint.

Built for durability, precision, and scalability, SRT Clarifiers set new standards for juice clarification in modern sugar and process industries.

How It Works

Uniform Juice Feeding

Gravity-Assisted Settling

Mud Withdrawal

Clear Juice Overflow

Key Advantages

High Juice Quality

Special juice distribution ensures ultra-clear juice with minimal turbidity.

Reduced Sugar Degradation

Short retention time minimizes sugar breakdown even at high temperatures.

Efficient Mud Removal

Reliable mud withdrawal prevents carryover, maintaining consistent juice quality.

Compact, Scalable Design

Handles plant capacities from 500 TCD to 20,000 TCD with minimal footprint.

Lower Operating Costs

Optimized flocculant dosing reduces chemical use and operational expenses.

Durable Construction

Internals in SS304 provide long-term reliability in industrial conditions.

High Juice Quality

Special juice distribution ensures ultra-clear juice with minimal turbidity.

Compact, Scalable Design

Handles plant capacities from 500 TCD to 20,000 TCD with minimal footprint.

Reduced Sugar Degradation

Short retention time minimizes sugar breakdown even at high temperatures.

Lower Operating Costs

Optimized flocculant dosing reduces chemical use and operational expenses.

Efficient Mud Removal

Reliable mud withdrawal prevents carryover, maintaining consistent juice quality.

Durable Construction

Internals in SS304 provide long-term reliability in industrial conditions.

Salient Features

Specially engineered juice distribution system to prevent short-circuiting.

Low turbidity, ultra-clear juice output.

Short residence time reducing sugar degradation.

Gentle, consistent mud withdrawal mechanism.

Minimal juice carryover into clear juice stream.

Customizable sizing for small to very large sugar plants.

Reduced flocculent requirement, lowering operating costs.

Robust SS304 construction for long-term durability.

Applications Across Industries

SED SRT Clarifiers deliver reliable performance in:

Sugar Mills

Beverage & Food Processing

Bio-based Industries

Why Partner with SED?

SED combines precision engineering, process expertise, and operational support to deliver SRT Clarifiers that optimize separation, enhance efficiency, and maintain juice quality across all plant sizes.

From design to commissioning and after-sales service, SED ensures that your clarification process is scalable, reliable, and sustainable.

Frequently Asked Questions

Revolutionizing Efficiency. Redefining Standards.

Enhance your juice clarification process with SED’s SRT Clarifier - engineered for ultra-clear juice, operational efficiency, and long-term reliability.