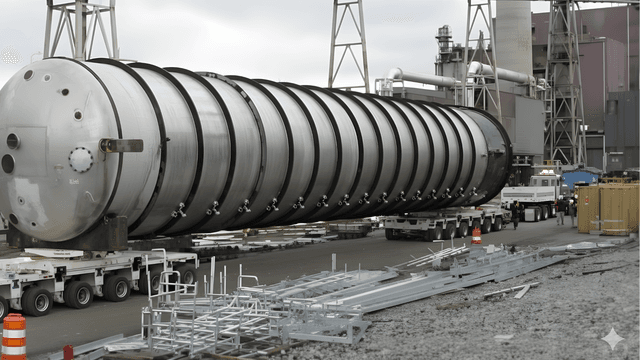

A Falling Film Tubular Evaporator is a versatile and highly efficient technology for concentrating liquids, especially for heat sensitive materials due to its excellent heat transfer characteristics and short retention time.

Read More

A Plate Type Falling Film Evaporator (PTFFE) is a compact, modular and highly energy-efficient heat exchange system accommodated in minimum footprint area and widely used for concentrating liquids in industries such as sugar, food processing, chemicals, wastewater etc.

Read More

A Forced Circulation Evaporator (FCE) concentrates highly viscous, high fouling, and crystalizing solutions using a tubular calandria and circulator/axial pump for efficient operation under vacuum or pressurized conditions.

Read More

A vacuum based Technology in which fluid starts boiling below its normal Boiling point temperature. This evaporator requires no continuous external steam input for operation and can generate clean water at a minimal cost.

Read More

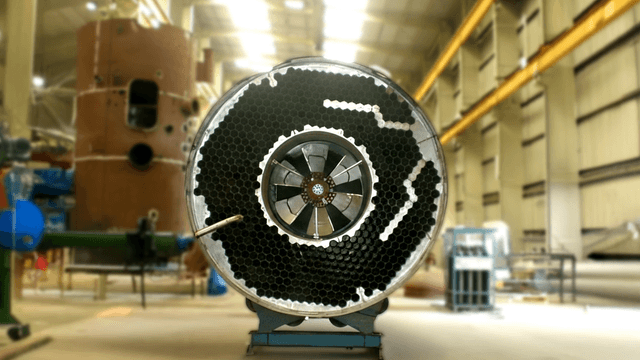

Introducing the Honeycomb Calandria Pan design, a game-changing solution in sugar manufacturing that offers a multitude of benefits aimed at optimizing the crystallization process and enhancing overall efficiency.

Read More

SCP is the amalgamation of uniform crystallization and has opened the gateway to the highest steam economy by minimizing the demand of pressure and ΔT,

Read More

The Shell & Tube Condensate Heater; commonly known as a Duplex Heater is a high-efficiency liquid-liquid heat exchanger used for juice heating prior to clarification in sugar processing plants.

Read More

Direct contact Heater (DCH) is designed to heat the process fluid to the temperature of heating vapor achieving almost zero approach. Utilizing the lower grade heat & improving the overall energy efficiency. Minimum maintenance and cleaning requirements make DCH the top heating solution.

Read More

The Condensate Flash System (or Flash Ciar) is a heat Recovering mechanism from condensate Streams with the aid of horizontal multi-chambered Condensate flash vessel which Improves energy efficiency.

Read More

The Molasses Conditioner by SED is an innovative direct-contact device designed to efficiently dissolve sugar crystals in molasses without adding water utilizing the heat content from non-condensable gases (NCG) or low-pressure vapors, it achieves substantial steam and power savings in sugar plants.

Read More

The SED Agitator is engineered for highly viscous solutions involving liquid-liquid or liquid-solid agitation, operating efficiently across low to medium speed ranges.

Read More

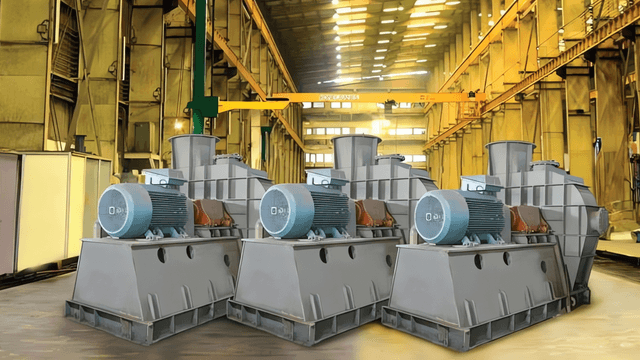

Our high-efficiency Mechanical Vapor Recompression (MVR) system, (EffiFlow Turbo Fan) is designed to dramatically reduce energy consumption and operational costs in industrial evaporation, distillation, and rying processes.

Read More

The Paddle Dryer is a drying system designed for efficient thermal processing of materials with good thermal stability, such as pastes, powders, and granules.

Read More

The SED Sugar Melter is a specialized system designed for efficient and consistent melting of sugar in refineries, cane, and beet sugar factories.

Read More

SED distillation columns are engineered to maintain minimal pressure drop (low ∆P) across trays or packing.

Read More

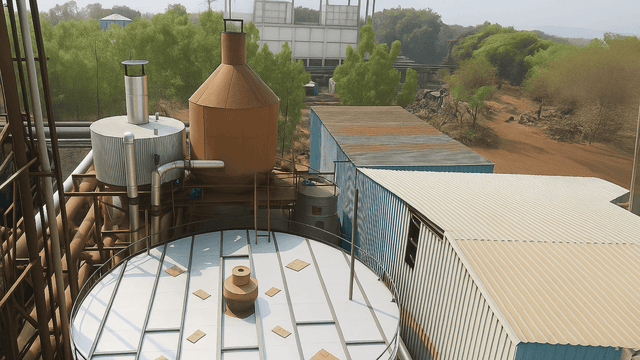

Innovative Separation Technology Designed for Performance, Sustainability, and Precision At Spray Engineering Devices Ltd.

Read More

Spray Ponds or Mist Cooling System is an innovative application of modern materials, designs, and architecture to a century old concept

Read More

A condenser is a vacuum-generating device that uses the kinetic energy of a motive fluid—typically water or high-pressure steam—to entrain a secondary fluid or gas from the suction side.

Read More

A jet ejector is a static, non-mechanical device used to create vacuum or remove nonn condensable gases by converting the pressure energy of a high-velocity motive fluid i.e water into kinetic energy through a converging nozzle.

Read More

A spray nozzle is a component used condensers, which are common in sugar and other process industries.

Read More

A fermenter (bioreactor) is a precision-engineered vessel designed to cultivate microorganisms or cells under controlled conditions—such as temperature, pH, aeration, and mixing—to produce products like biofuels, pharmaceuticals, enzymes,food, and biogas.

Read More

A short retention time clarifier is a vertical cylindrical vessel having specifically designed juice feeding arrangement and mud withdrawal system.

Read More

A Milling System, also known as a Milling Tandem, is a critical unit in sugar manufacturing designed to extract juice from prepared sugarcane through mechanical crushing.

Read More

A Jaggery Cooling Belt Conveyor is a post-processing unit engineered to cool molded jaggery efficiently and hygienically after the milling stage.

Read More