Efficient. Sustainable. Engineered for High-Performance Separation.

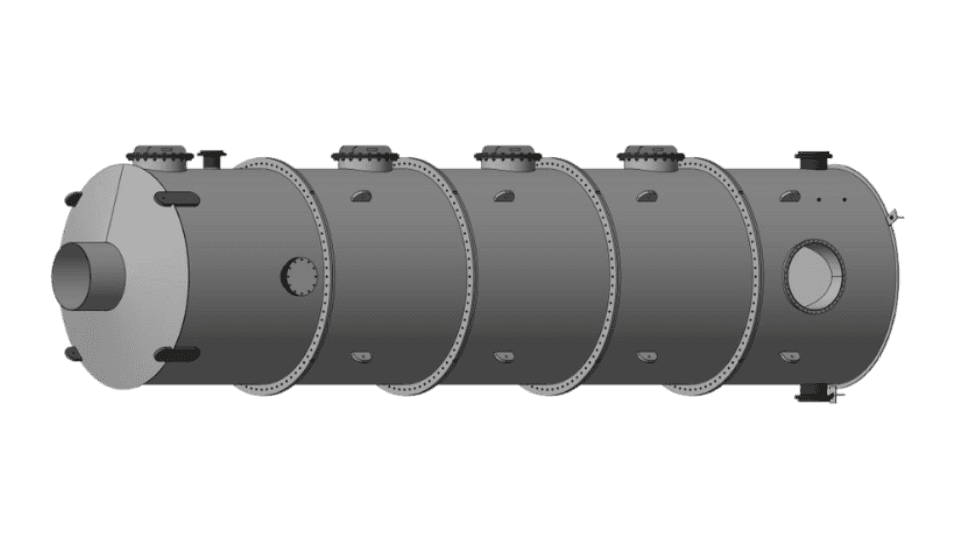

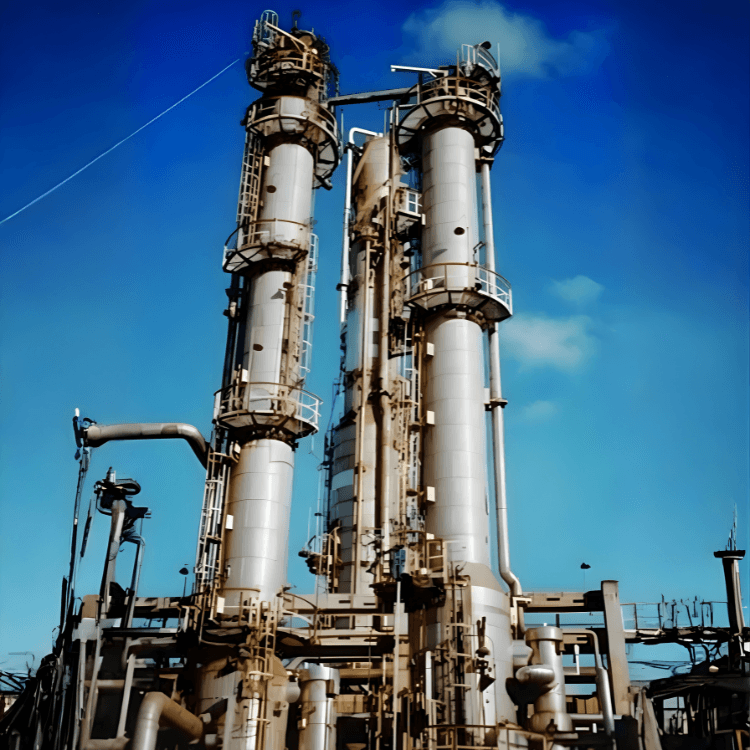

SED’s Stripper Column is a high-efficiency separation system designed for pollutant removal, solvent recovery, and Zero Liquid Discharge (ZLD) applications. Built to operate under low ΔP (delta pressure) conditions, it delivers superior stripping efficiency with minimal energy consumption.

With advanced vapor–liquid contact internals, robust construction, and process-specific customization, SED’s stripper columns set new benchmarks in environmental compliance and industrial sustainability - from biofuel recovery to wastewater treatment.

How It Works

Feed Introduction

Mass Transfer Zone

Volatile Removal

Purified Liquid Outlet

This optimized configuration ensures high stripping efficiency, low steam consumption, and minimal pressure drop; all tailored to your process needs.

Key Advantages

High Pollutant Removal (up to 99%)

Achieves efficient elimination of VOCs, solvents, and dissolved gases across diverse feed compositions.

Low Energy Consumption

Designed for reduced steam requirements through improved thermal integration and vapor management.

Consistent Performance

Uniform liquid distribution and advanced internals guarantee stable operation even under fluctuating load conditions.

Vacuum & Atmospheric Operation

Capable of both vacuum and pressure stripping, enhancing versatility across applications.

Turnkey EPC Integration

Delivered with complete process design, automation, and commissioning support for seamless plant operation.

High Pollutant Removal (up to 99%)

Achieves efficient elimination of VOCs, solvents, and dissolved gases across diverse feed compositions.

Vacuum & Atmospheric Operation

Capable of both vacuum and pressure stripping, enhancing versatility across applications.

Low Energy Consumption

Designed for reduced steam requirements through improved thermal integration and vapor management.

Turnkey EPC Integration

Delivered with complete process design, automation, and commissioning support for seamless plant operation.

Consistent Performance

Uniform liquid distribution and advanced internals guarantee stable operation even under fluctuating load conditions.

Salient features

Integrated Mist Eliminator

Removes fine droplets, ensuring clean vapor and reduced carryover.

Optimized Liquid Distribution System

Uniform flow across the column cross-section for superior stripping efficiency.

Vacuum Stripping Capability

Enables energy-efficient operation by lowering boiling points.

High Stripping Efficiency

Proprietary internals maximize contact area and mass transfer rates.

Versatile Material of Construction (MOC)

Available in MS, SS304/316, Duplex, Cladded, Titanium, and exotic alloys

Custom Engineered

Tailored for your process stream, pollutant type, and operating conditions.

Applications Across Industry

SED’s stripper columns deliver reliable, energy-efficient separation performance across multiple industries:

Biofuels & Ethanol Plants

Chemical & Petrochemical Industries

Pharmaceutical & Bulk Drug Manufacturing

Food & Beverage Processing

Distilleries (Grain, Molasses & 2G Ethanol)

Pulp, Paper, Textile & Dye Units

Why Partner with SED?

At SED, we combine decades of process expertise with advanced design and manufacturing capabilities to deliver turnkey separation systems that maximize operational efficiency and sustainability.

Our integrated EPC approach covers everything from process analysis and column design to automation, installation, and commissioning - ensuring performance that exceeds expectations in every industry.

Our Expertise Includes:

- Process Design & Simulation

- Custom Fabrication & Quality Assurance

- Automation, Instrumentation & Control

- End-to-End EPC Project Delivery

With SED, you partner with a team committed to innovation, reliability, and environmental stewardship.

Frequently Asked Questions

Revolutionizing Efficiency. Redefining Compliance.

Experience next-generation stripping and purification with SED’s Stripper Column - engineered for sustainability, reliability, and superior performance across industrial processes.